Abrasive glass beads are a highly versatile and effective media used in a variety of surface treatment processes, especially in metal cleaning, rust removal, and finishing applications. Whether you’re involved in automotive restoration, aerospace maintenance, or general metal fabrication, glass beads offer several benefits that make them an ideal choice for these tasks.

Abrasive glass beads are small, round particles made from soda-lime glass. They are used as a media in blasting processes, where high-pressure air propels the beads onto surfaces to clean, polish, or smooth them. The round shape of the glass beads makes them less aggressive compared to angular blasting media like aluminum oxide, resulting in a more delicate surface treatment.

One of the primary uses of abrasive glass beads is for metal surface cleaning. Over time, metal parts accumulate contaminants like oil, dirt, or oxidation. Glass bead blasting can effectively clean the surface without damaging the metal underneath. It is especially useful for cleaning delicate parts such as engine components, molds, and tools that require a non-abrasive cleaning process.

Rust can severely weaken metal components, leading to performance degradation and eventual failure. Glass beads are excellent for removing rust from metal surfaces. They clean the rust away while preserving the structural integrity of the underlying material. This makes glass beads ideal for automotive restoration, where preserving the original shape and function of parts is crucial.

Glass beads are also widely used to prepare surfaces for painting, powder coating, or plating. The blasting process roughens the surface slightly, allowing coatings to adhere better and last longer. The beads leave behind a smooth, uniform finish that ensures the even application of paints and coatings, resulting in a superior final product.

In addition to cleaning and rust removal, glass beads can be used for polishing metal surfaces. They are particularly effective at producing a satin or matte finish on stainless steel and other metals, giving the material a visually appealing, uniform texture. This is often done in industries like jewelry making and decorative metalwork.

Compared to more aggressive media like aluminum oxide or steel grit, glass beads are gentler on the surfaces being treated. This makes them perfect for cleaning and finishing softer materials or parts that have intricate details. They remove surface contaminants without causing pitting or etching, which is especially important for delicate or precision components.

Glass beads can be reused multiple times before breaking down, making them a cost-effective blasting media. Depending on the pressure and application, they can be cycled through the blasting process several times, reducing the need for frequent replacements and lowering overall project costs.

Abrasive glass beads are an inert, non-toxic media, meaning they don’t introduce harmful chemicals into the environment. Since they are made from natural materials and do not contain free silica, they pose less health risk to workers compared to other blasting materials that might produce hazardous dust.

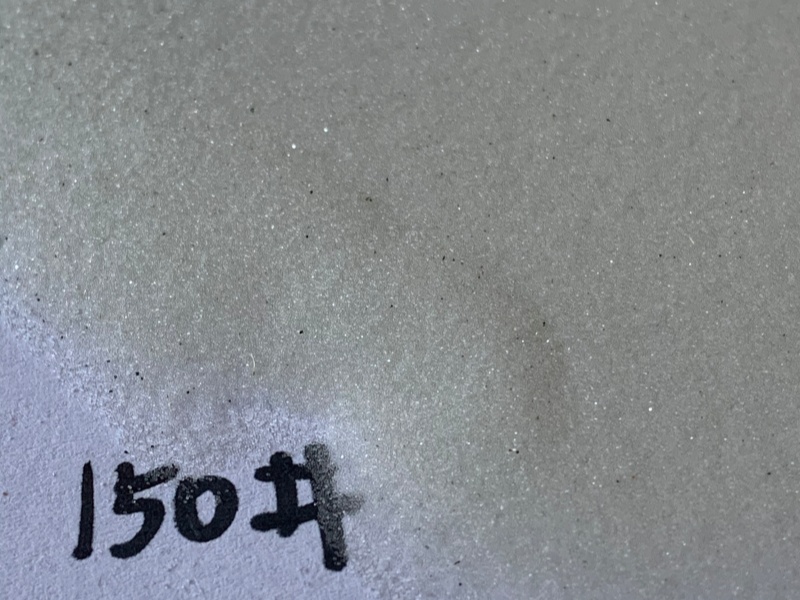

Glass beads come in various sizes, which influence the finish and outcome of the blasting process. Larger beads are more effective for heavy-duty cleaning and rust removal, while smaller beads are used for polishing and producing smoother finishes. Choosing the right bead size depends on the specific requirements of your project.

Aerospace: Cleaning turbine blades, engine parts, and other critical components.

Automotive: Rust removal and surface preparation in vehicle restoration projects.

Metalworking: Polishing and smoothing metal parts for tools, molds, and decorative items.

Manufacturing: Prepping surfaces for coating or painting, especially in mass production.

Abrasive glass beads provide an efficient, cost-effective, and environmentally friendly solution for a variety of metal cleaning, rust removal, and polishing tasks. Their versatility, non-aggressiveness, and reusability make them a preferred choice across many industries. By choosing the right bead size and blasting conditions, you can achieve superior surface finishes while preserving the integrity of the material.

Whether you're restoring a vintage car, maintaining aircraft parts, or simply looking to extend the life of metal tools, abrasive glass beads offer a reliable solution to meet your surface treatment needs.