When it comes to abrasive blasting, choosing the right media is crucial for achieving the desired surface finish and performance. Glass beads are a popular choice for many applications, and they offer several advantages over other blasting media. Here’s a comparison of glass beads with other common blasting media and why glass beads stand out.

Surface Finish:

Glass Beads: Provide a smooth, satin, or matte finish, making them ideal for applications requiring a high-quality surface appearance.

Aluminum Oxide: More aggressive and creates a rougher surface, which is suitable for heavy-duty cleaning and surface preparation.

Material Preservation:

Glass Beads: Non-abrasive and gentle on surfaces, preserving the integrity of the material.

Aluminum Oxide: Highly abrasive and can cause significant wear on the material, potentially leading to surface damage.

Reusability:

Glass Beads: Can be reused multiple times, making them cost-effective and environmentally friendly.

Aluminum Oxide: Tends to break down more quickly, reducing its reusability.

Surface Finish:

Glass Beads: Ideal for achieving a uniform and smooth finish.

Silicon Carbide: Extremely aggressive and creates a very rough surface, suitable for heavy-duty material removal.

Material Preservation:

Glass Beads: Gentle on surfaces, making them suitable for delicate materials.

Silicon Carbide: Can cause significant material removal and surface damage.

Cost:

Glass Beads: Generally more affordable and offer good value due to their reusability.

Silicon Carbide: More expensive and less cost-effective due to its rapid breakdown.

Surface Finish:

Glass Beads: Provide a clean, smooth finish without significant material removal.

Steel Shot: Creates a peened surface, which is beneficial for stress relief but may not be suitable for all applications.

Material Preservation:

Glass Beads: Non-abrasive and ideal for preserving the original surface.

Steel Shot: More aggressive and can cause surface deformation.

Weight and Handling:

Glass Beads: Lightweight and easier to handle.

Steel Shot: Heavier and requires more robust equipment for handling.

Surface Finish:

Glass Beads: Achieve a smooth and uniform finish, suitable for aesthetic applications.

Garnet: More aggressive and creates a rougher surface, ideal for heavy-duty cleaning and preparation.

Material Preservation:

Glass Beads: Gentle on surfaces, preserving the material’s integrity.

Garnet: More abrasive and can cause surface wear.

Environmental Impact:

Glass Beads: Produce minimal dust and are environmentally friendly due to their reusability.

Garnet: Can produce more dust and is less reusable.

Surface Finish:

Glass Beads: Provide a smooth, high-quality finish.

Plastic Media: Less aggressive and suitable for delicate surfaces but may not achieve the same level of finish as glass beads.

Material Preservation:

Glass Beads: Non-abrasive and ideal for preserving the original surface.

Plastic Media: Very gentle and suitable for sensitive materials.

Durability:

Glass Beads: More durable and can be reused multiple times.

Plastic Media: Less durable and may break down more quickly.

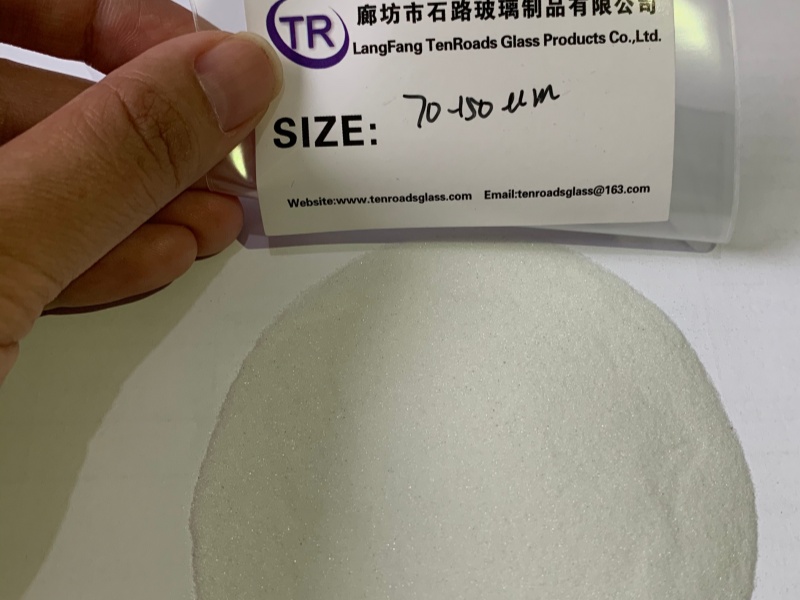

Uniform Surface Finish: Glass beads provide a consistent and smooth finish, making them ideal for applications requiring high-quality surface aesthetics.

Gentle on Surfaces: Their non-abrasive nature ensures that the base material is preserved, making them suitable for delicate and sensitive surfaces.

Reusability: High-quality glass beads can be reused multiple times, offering cost-effectiveness and environmental benefits.

Versatility: Suitable for a wide range of applications, from cleaning and polishing to surface preparation and peening.

Minimal Dust Production: Glass beads produce minimal dust, enhancing workplace safety and reducing environmental impact.

Glass beads stand out as a versatile, cost-effective, and environmentally friendly blasting media. Their ability to provide a uniform and smooth finish while preserving the integrity of the material makes them an excellent choice for a wide range of applications. Whether you are working on delicate surfaces or require a high-quality finish, glass beads offer numerous advantages over other blasting media.