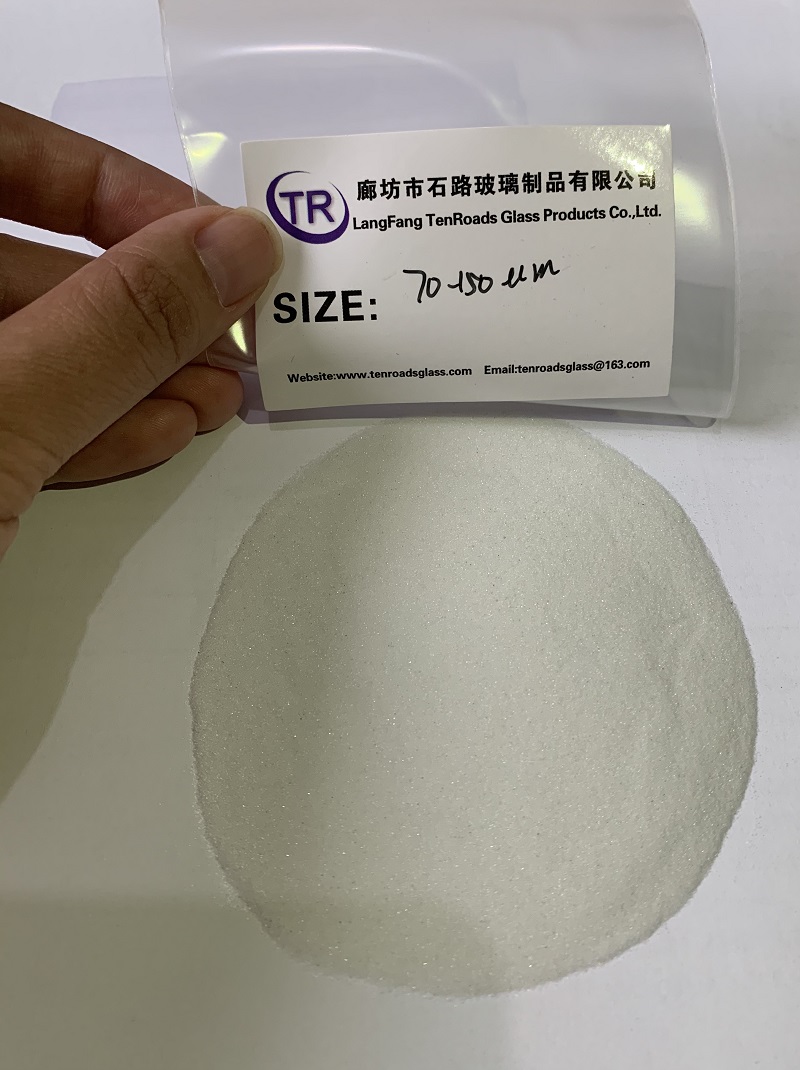

Sandblasted glass beads are a kind of organic material with quality, low conductivity and higher strength, which is produced by processing with borosilicate material. And this product is also widely used in our life. We introduce you its advantages and its use in industry.

.jpg)

Sandblasting glass beads are artificial abrasives, so the selection of materials and production process is very important. After the glass beads are formed, there are many irregular distributions in the beads, so it needs to be annealed, otherwise the uneven residual force will reduce the strength of the glass beads. The technique of annealing also directly affects the strength of glass beads.

Glass beads only have good uniformity, in order to be evenly stressed during the process of blasting work, the breaking rate is reduced, and the service life is improved.

The rounding rate of glass beads also affects the mechanical strength. Under the same material and the same pressure, the more sharp type glass beads, the lower the strength; the higher the rounding rate, the higher the strength.

Soft and hard quality material, that is, a certain mechanical strength. Hardness up to 6-7 Mohs, and have enough elasticity, can be used repeatedly several times, not easy to break. The service life is more than three times longer than ordinary glass beads.

Good uniformity - roundness ≥ 80%, uniform particle size. After blasting, the brightness coefficient of the sandblaster remains uniform, and it is not easy to leave a watermark.

Smooth and impurity-free - the appearance of spherical particles, no impurities; smooth surface, good finish, to meet international and domestic standards.

Sandblasted glass beads are longer than any other media, so they have good chemical stability, will not pollute the processed metal, can accelerate the cleaning, while maintaining the processing accuracy of the original material.

Sandblasted glass beads can be applied to the surface matting of stainless steel products, molds, semiconductor devices, metal tubes, non-ferrous metal cleaning.

Sandblast glass beads are cleaning products for various metal products. By using shot peening machine use can enhance the fatigue life of the machine parts. Can be on semiconductor devices, tubes on the plastic seal before the tin cleaning to remove the edge of the thorns, but also can act to the processing of hardware products.

TENROAD glass beads are made of non-alkaline calcium and sodium glass beads as raw material, and the broken glass is melted into spheres and then annealed to eliminate internal stress and prevent breakage. The hardness, toughness, silicon content and rounding rate of our glass beads are all higher than the American Society of Automotive Engineering standards and meet the national environmental requirements. If you need to buy, please contact us.