Blasting operations require a balance between effectiveness and precision, especially when working with delicate surfaces. Fine glass beads offer a unique solution for surface treatment that combines both. These tiny, spherical particles are widely used in abrasive blasting for tasks such as cleaning, deburring, and surface finishing. In this blog, we explore the benefits, applications, and considerations of using fine glass beads for blasting.

Fine glass beads are small, smooth, and spherical particles typically made from soda-lime glass. Unlike angular blasting media like aluminum oxide or steel grit, glass beads have a round shape, making them much less aggressive. This characteristic allows them to be used in more delicate applications without damaging or altering the underlying surface.

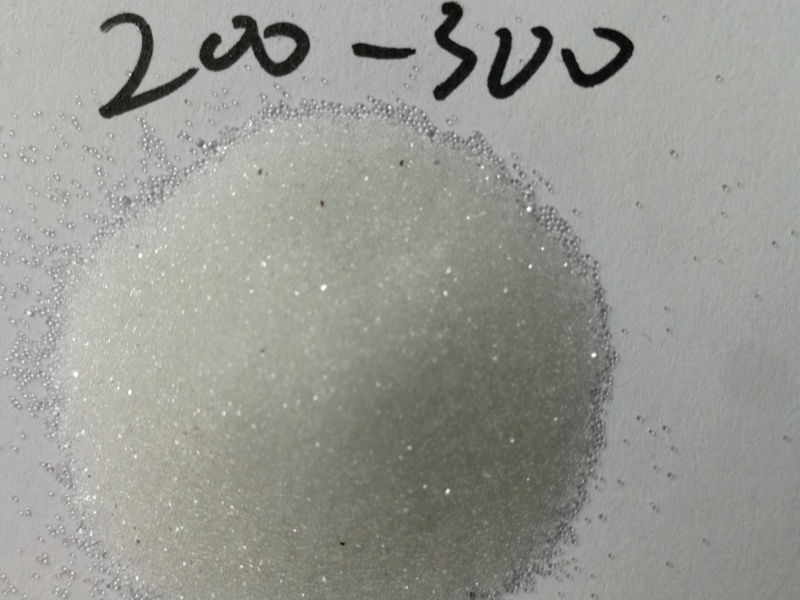

Glass beads are available in a range of sizes, with fine glass beads typically falling on the smaller end of the scale. These fine beads are ideal for creating a smooth, satin-like finish on various surfaces.

One of the major benefits of fine glass beads is their precision. When used in blasting, these beads can clean and polish surfaces without causing etching, pitting, or surface deformation. This is particularly important when working with sensitive materials like stainless steel, aluminum, or soft alloys, which can be easily damaged by more aggressive media.

Fine glass beads are often chosen for cosmetic surface treatments, where preserving the aesthetic integrity of the material is essential. They leave behind a smooth and uniform finish, making them perfect for applications that require a delicate touch.

Fine glass beads are non-toxic and inert, meaning they don’t release harmful chemicals or create toxic dust during the blasting process. This makes them a safer alternative for both operators and the environment. Additionally, glass beads are recyclable and can be reused multiple times before they break down, significantly reducing waste and costs associated with media replacement.

Fine glass beads provide a consistent blasting effect. The uniformity of the particles ensures an even distribution across the surface being treated, leading to a smooth and consistent finish. This consistency is important in industries like automotive, aerospace, and jewelry making, where surface quality can directly affect the functionality and appearance of the product.

Fine glass beads are excellent for cleaning metal surfaces, removing contaminants like oil, dirt, and light oxidation without damaging the base material. This makes them ideal for cleaning delicate machine parts, tools, and molds.

Although fine glass beads are less aggressive than other media, they are still highly effective at removing light rust and corrosion. For applications where preserving the surface structure is critical, fine glass beads offer the right balance of cleaning power and material preservation.

In surface preparation for painting, coating, or plating, fine glass beads create a uniform texture that enhances adhesion. Unlike coarser media that can create rough or uneven surfaces, fine beads ensure that coatings apply evenly and last longer.

For industries that require a smooth, polished finish—such as jewelry making, decorative metalwork, and medical device manufacturing—fine glass beads provide an excellent polishing medium. They are frequently used to create a satin or matte finish on metals, resulting in a high-quality, visually appealing surface.

When selecting fine glass beads for blasting, the size and application are key factors to consider. Smaller beads (with sizes measured in microns) are better suited for precision polishing and cleaning, while slightly larger fine beads can handle tasks like rust removal or surface prep.

It's also essential to choose the correct blasting equipment. Fine glass beads work best in blasting cabinets and controlled environments where air pressure and blasting conditions can be finely adjusted for optimal performance.

Fine glass beads are an ideal choice for industries that require a balance of precision, efficiency, and surface preservation. Their ability to clean, polish, and prepare surfaces without causing damage makes them a go-to solution in many high-precision applications.

Whether you’re preparing metal surfaces for coating, removing light rust, or polishing delicate materials, fine glass beads offer a versatile and eco-friendly blasting media that delivers exceptional results. By investing in fine glass beads, you can achieve superior surface finishes while reducing operational costs through media reuse and reduced waste.

If you are looking for a reliable and efficient way to enhance your blasting process, fine glass beads are an excellent choice to consider for your next project.