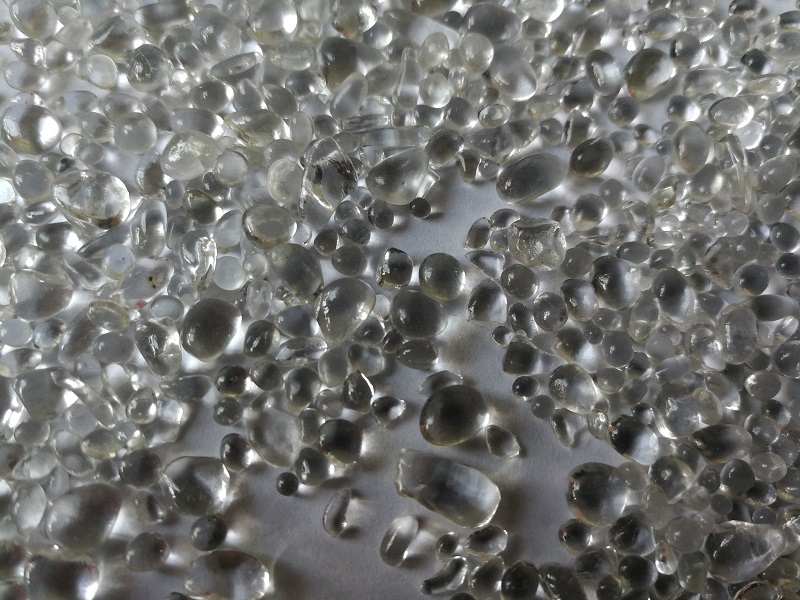

Glass beads and crushed glass are both effective abrasives that produce the desired finish on parts. Glass beads are typically used in blasting cabinets or recyclable types of blasting operations. Crushed glass is best for removing heavy coatings, paint layers or rust to reveal a clean and bare surface.

If you want to determine which abrasive is best for the job at hand, comparing glass beads to crushed glass is a key way to determine if one of these options is right for you.

.jpg)

Glass beads are best suited for finishing metals. They can be used for frosting and etching glass, as well as other typical applications.

Cleaning (great for surface preparation that does not alter tolerances or create ferrous contaminants)

Finishing (different sizes produce a unique blend of surface finishes and machining marks)

Shot blasting (reduces tensile stresses in metal parts and improves fatigue limits)

Deburring (successfully removes burrs without damaging any parts, resulting in a smooth blasted surface)

One of the benefits of using glass beads is that they are environmentally friendly and do not contain free silica, which is a common problem in metal finishing operations. Usually present in conventional blasting media, free silica releases harmful chemicals during the wear process. While silica sand is still an option for companies, more regulations are needed due to the increased risk of serious respiratory illnesses in workers.

The size of the beads, your particular workpiece shape, nozzle distance, air pressure and type of blasting system all play a critical role in the final finish and abrasive consumption. If used properly, you can recycle glass beads many times over. When selecting glass bead blasting equipment, consider using a blasting cabinet to help recycle this blasting media for efficient reuse. Whichever type of glass beads you choose, you will achieve a bright, smooth and more satin-like finish.

Crushed glass will produce greater etching on your workpiece due to its irregular broken shape, making it suitable for surface finishes where subsequent coatings may be applied. Compared to other abrasives, our crushed glass excels in a variety of applications due to its performance, health and environmental benefits.

100% recycled glass can be reused multiple times, facilitating safe disposal.

It is environmentally friendly and has non-toxic chemical properties that reduce the risk of contamination.

It is non-reactive and chemically inert, reducing rusting and making it safe for use around water.

It contains less than 1% free silica compared to silica sands that contain up to 99% free silica.

Our SDS does not list beryllium, a heavy or toxic metal commonly found in slag and other abrasives.

The natural white sandblasted finish creates an attractive final finish step.

It significantly reduces the embedding problems that occur in slag blasting media by up to five times.

It is translucent, meaning visibility and productivity are greatly enhanced.

It is less dense than other abrasives, which reduces material usage and lowers media costs.

While both are commonly used to finish metal surfaces, sandblasting and grit blasting are different processes that are beneficial for different environments and projects. Sandblasting with glass beads is less traditional. However, you can use a broken glass blasting media with a standard blasting can.

TENROADS has a variety of glass beads for sale for road markings, sandblasting, decorative items and more, so contact us if you need to buy!