In industrial surface treatment processes, efficiency, cost-effectiveness, and environmental sustainability are crucial factors. Recyclable abrasive glass media, particularly glass beads, offer an ideal solution for maximizing efficiency in blasting operations. Whether used for surface cleaning, rust removal, or finishing applications, this type of blasting media ensures outstanding results while maintaining sustainability. In this blog, we explore the key benefits and applications of using recyclable abrasive glass media and how it can enhance your surface treatment processes.

Recyclable abrasive glass media, typically made from soda-lime glass, is widely used in blasting applications due to its efficiency and environmentally friendly properties. Unlike traditional sandblasting materials, glass media is inert and does not contain toxic substances. Its recyclability allows it to be used multiple times, significantly reducing material waste and operational costs.

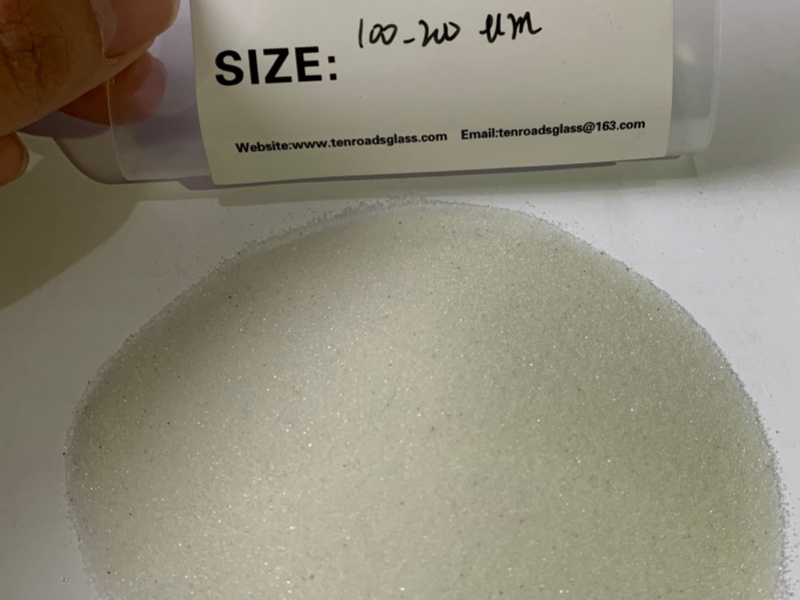

Glass beads, for instance, are rounded, non-aggressive particles that are perfect for delicate surface treatments. They can be reused many times, making them a cost-efficient and eco-conscious choice in a variety of industries.

One of the most significant advantages of recyclable glass media is its reusability. Depending on the type of blasting process, glass beads can be recycled numerous times before losing effectiveness. This makes it much more economical compared to single-use abrasive materials like sand or silicon carbide.

The durability of the glass media also helps reduce replacement costs, allowing businesses to use fewer resources and extend the lifespan of the blasting material.

As the world moves toward greener industrial processes, recyclable glass media stands out as an eco-friendly alternative. Since it’s made from natural materials and does not produce harmful chemical byproducts during use, glass media minimizes the environmental impact associated with blasting operations. Additionally, its reusability further cuts down on waste, aligning with sustainability goals.

Unlike other abrasive materials that may contain harmful toxins like silica, glass beads are non-toxic, providing a safer working environment for operators while reducing harmful dust emissions during blasting.

Recyclable glass media is extremely versatile and can be used for a variety of tasks across different industries. Whether you need to clean metal parts, remove rust, or prepare surfaces for coating, glass beads provide an effective and non-damaging solution. Common industries where glass media is frequently used include automotive, aerospace, metalworking, and marine sectors.

Additionally, because glass media is non-abrasive compared to angular blasting materials, it is especially suited for polishing surfaces and delicate cleaning of parts that require a smooth finish.

When preparing surfaces for coating or painting, glass beads are the preferred choice due to their ability to create a consistent and uniform finish. This helps improve the adhesion of paints, coatings, and other finishes, leading to higher-quality results. The spherical shape of the beads ensures a smooth and even surface, which is critical in industries that demand precision.

By switching to recyclable glass media, businesses can achieve higher efficiency in several ways:

Fewer Material Replacements: Since glass beads can be reused, companies can decrease the frequency of material replacement, leading to reduced downtime in operations.

Faster Blasting Process: Glass media provides consistent performance in blasting applications, ensuring quicker results without sacrificing quality. This speed enhances overall productivity, allowing more projects to be completed in less time.

Lower Disposal Costs: The recyclable nature of glass media means less waste is generated, resulting in fewer disposal fees and less environmental impact. This contributes to a more sustainable and cost-effective business model.

In industries like automotive restoration and marine maintenance, rust removal is a critical task. Recyclable glass beads can efficiently remove rust without damaging the base metal, making it a superior choice for preserving the integrity of parts and equipment.

Glass beads are perfect for cleaning industrial equipment, tools, and machinery. Their gentle abrasive action ensures contaminants like oil, dirt, and oxidation are removed without leaving surface damage, making them ideal for delicate parts.

Before applying paint, powder coating, or other finishes, surfaces need to be properly prepped. Glass media is excellent at preparing surfaces by creating a slight texture that improves the bonding of coatings.

In metalworking and jewelry making, glass beads are frequently used for polishing and deburring to achieve a smooth, aesthetically pleasing finish. Their non-aggressive nature ensures that intricate details are not compromised during the process.

Recyclable abrasive glass media is a game-changer in the blasting industry, providing an eco-friendly, cost-efficient, and highly effective solution for surface treatment needs. By incorporating glass beads into your operations, you can maximize efficiency while reducing waste, saving on material costs, and supporting a greener business model.

If you're looking to improve your blasting efficiency without sacrificing quality, recyclable glass media offers a sustainable and versatile option that’s ideal for a wide range of industrial applications.