Blasting with glass beads is a highly effective method for achieving precision in surface finishing. Whether you are working on delicate components or aiming for a specific texture, the following tips and techniques can help you achieve the desired results with precision.

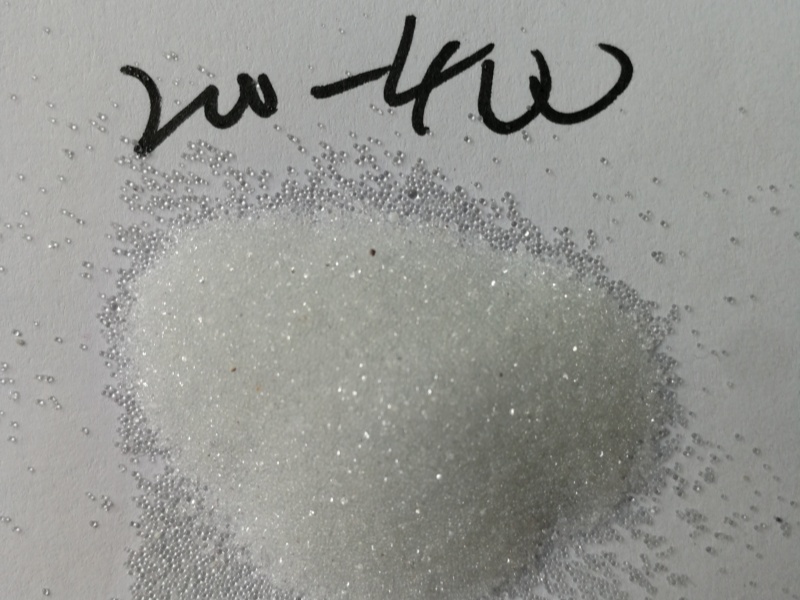

Fine Beads for Delicate Surfaces: Use smaller glass beads for delicate surfaces or when a finer finish is required. Fine beads are less aggressive and provide a smoother finish.

Coarse Beads for Heavy-Duty Applications: Larger beads are more aggressive and suitable for removing heavy contaminants or achieving a rougher texture.

Lower Pressure for Precision: Use lower blasting pressure for more precise control, especially on delicate or intricate surfaces. This reduces the risk of damaging the material.

Higher Pressure for Efficiency: Higher pressure can be used for faster material removal but should be carefully controlled to avoid over-blasting.

Optimal Distance: Maintain a consistent distance between the blasting nozzle and the surface. Typically, a distance of 6-12 inches is recommended, but this can vary based on the specific application.

Consistent Angle: Keep the nozzle at a consistent angle, usually around 45 degrees, to ensure even coverage and avoid creating uneven patterns.

Quality Nozzles: Use high-quality nozzles designed for glass bead blasting. The nozzle size and shape can affect the precision and efficiency of the blasting process.

Blasting Cabinets: For small parts or detailed work, consider using a blasting cabinet. This provides a controlled environment and helps contain the media.

Consistent Media Flow: Ensure a consistent flow of glass beads to avoid fluctuations in blasting intensity. Inconsistent media flow can lead to uneven surface finishes.

Media Recycling: Use a recycling system to maintain a steady supply of clean, uncontaminated glass beads. This also helps reduce waste and costs.

Avoid Overheating: Blasting can generate heat, which may affect the material being worked on. Monitor the surface temperature and allow cooling periods if necessary to prevent warping or other heat-related issues.

Clean Equipment: Regularly clean the blasting equipment to prevent clogging and ensure consistent performance. Accumulated debris can affect the precision of the blasting process.

Inspect Components: Periodically inspect and replace worn-out components such as nozzles and hoses to maintain optimal performance.

Trial Runs: Before working on the actual piece, conduct trial runs on sample pieces. This allows you to fine-tune the settings and techniques to achieve the desired finish without risking damage to the final product.

Protective Gear: Always wear appropriate protective gear, including gloves, goggles, and respiratory protection, to safeguard against potential hazards.

Ventilation: Ensure proper ventilation in the blasting area to minimize dust and airborne particles.

Record Settings: Document the settings and techniques used for each project. This helps in replicating successful results and maintaining consistency across similar tasks.

Standard Operating Procedures: Develop and follow standard operating procedures (SOPs) for glass bead blasting to ensure consistent and precise results.

Achieving precision with blasting glass beads requires careful attention to detail, proper equipment, and controlled techniques. By selecting the right bead size, adjusting pressure, maintaining consistent distance and angle, and following best practices, you can achieve high-quality, precise surface finishes. Regular maintenance, safety precautions, and thorough documentation further enhance the effectiveness and reliability of the blasting process.