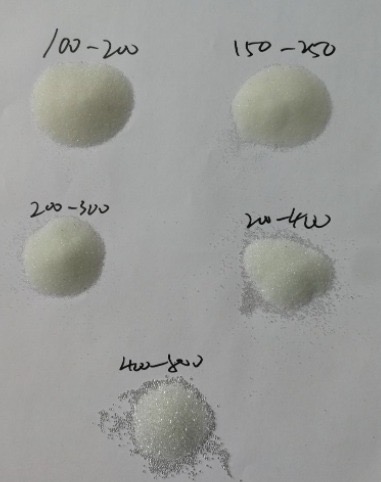

Glass beads are a kind of abrasive blasting consumables. At present, the common standard for sandblasting glass beads in the market is a maximum diameter of 850μm and a minimum of 100μm, and the particle size can be divided into various types according to specific intervals in common use and can be graded and proportioned according to different requirements.

In the process of sandblasting and shot blasting of different parts surface treatment, in the selection of abrasives, glass beads are often applied to

Various types of stainless steel products matte treatment

The cleaning of various molds

Various types of machine parts tensile stress removal

Various hardware products of shot peening and finishing processing

Surface treatment of all kinds of non-ferrous metal fittings and precision castings

Burr removal, oxide removal, rust removal, grinding and roughening, stress removal, etc. for all kinds of machine parts

In all kinds of sandblasting and shot blasting surface treatment consumables, glass beads compared with steel and stainless steel shot, the particle size can be less than 0.15mm, steel and stainless steel shot is widely used in metal blasting and surface treatment of some larger machine parts. Glass beads are more suitable for precision castings and non-ferrous metal parts.

In precision castings and non-ferrous metal parts, steel shot will deform the parts and leave marks and stress relief overload. Glass beads can be produced down to less than 0.05mm, and the proper size type has a smaller contact area with the part, which is less likely to damage the surface of the part, and has a more uniform stress relief and better matte finish. Please follow TENROADS to find more.

Sandblasted glass beads are divided into natural gas glass beads and coking gas glass beads according to the production process. In terms of usage efficiency, coking gas glass beads can generally be recycled 1-2 times, while natural gas glass beads can generally be recycled 3-4 times according to the actual application. In addition, the fan pressure and the ratio with other consumables also partially affect the durability. The processing effect of natural gas glass beads is also better than coking gas glass, which can be clearly compared in the actual use of customers. Therefore, the actual technical support of the glass beads becomes especially important.

With regard to the renewable advantages of glass beads, glass beads made from recycled flat glass have the advantage of long-term sustainability and cost advantages over other ore-based consumables.

1. Soft and hard quality material, that is, a certain mechanical strength, sio2 content greater than or equal to 68%, hardness up to 6-7 Mohs, and enough elasticity, can be used repeatedly several times, not easy to break. Spraying device effect is the same, the service life is more than three times longer than ordinary glass beads.

2, good uniformity - roundness ≥ 80%, uniform particle size. After blasting, the brightness coefficient of the sandblaster remains uniform, and it is not easy to leave a watermark.

3. irreplaceable - blasting glass beads as abrasive has the following advantages over any other abrasive: longer than any other media except metal abrasives, made of non-alkaline soda lime glass material, with good chemical stability, will not pollute the processed metal, can accelerate the cleaning, while maintaining the processing accuracy of the original object

4. Smooth and impurity-free - the appearance of spherical particles, no impurities; smooth surface, good finish, to meet international and domestic standards.

Sandblasting glass beads also have the advantage of being irreplaceable to each other compared with the supplies with diamond angle such as diamond angle glass sand, diamond sand and quartz sand. Glass beads, on the other hand, rarely leave traces on the surface of work devices after blasting and purification, and have a long-term unchanging effect. TENROAD sells high quality sandblasting glass beads, we have the qualified certificate, welcome you to visit our website, and also welcome you to contact our experts, we will answer your questions soon.