Blasting glass beads is a popular method for surface finishing due to its unique properties and benefits. This technique is widely used across various industries to achieve a smooth, clean, and aesthetically pleasing surface. Here’s how blasting glass beads enhance surface finishing:

Consistent Results: The spherical shape of glass beads ensures a uniform impact on the surface, resulting in a consistent texture. This is particularly important for applications requiring a smooth and even finish.

Matte and Satin Finishes: Glass beads can create a range of finishes from matte to satin, enhancing the visual appeal of the product.

Non-Abrasive Nature: Unlike more aggressive media, glass beads are less abrasive, making them ideal for delicate surfaces. They clean and polish without causing significant wear or damage.

Surface Preservation: This gentle approach helps preserve the integrity of the material, extending its lifespan and maintaining its structural properties.

Surface Preparation: Blasting with glass beads creates a slightly roughened surface, which improves the adhesion of coatings, paints, and other finishes. This is crucial for ensuring that the applied layers bond effectively and last longer.

Enhanced Coating Performance: Better adhesion leads to improved performance and durability of the coatings, reducing the need for frequent maintenance or reapplication.

Inducing Compressive Stress: Glass bead blasting can induce compressive stress on the surface of metal parts, a process known as peening. This helps to relieve tensile stress, which can lead to cracks and failures.

Increased Fatigue Resistance: By reducing tensile stress, glass bead peening enhances the fatigue resistance of the material, making it more durable and less prone to failure under cyclic loading.

Improved Appearance: The smooth and uniform finish achieved through glass bead blasting enhances the aesthetic appeal of the product. This is particularly important for consumer goods and decorative items.

Surface Brightening: Glass beads can also brighten the surface, giving it a clean and polished look that is visually appealing.

Wide Range of Materials: Glass beads can be used on a variety of materials, including metals, plastics, glass, and ceramics. This versatility makes them suitable for a wide range of applications, from automotive parts to medical devices.

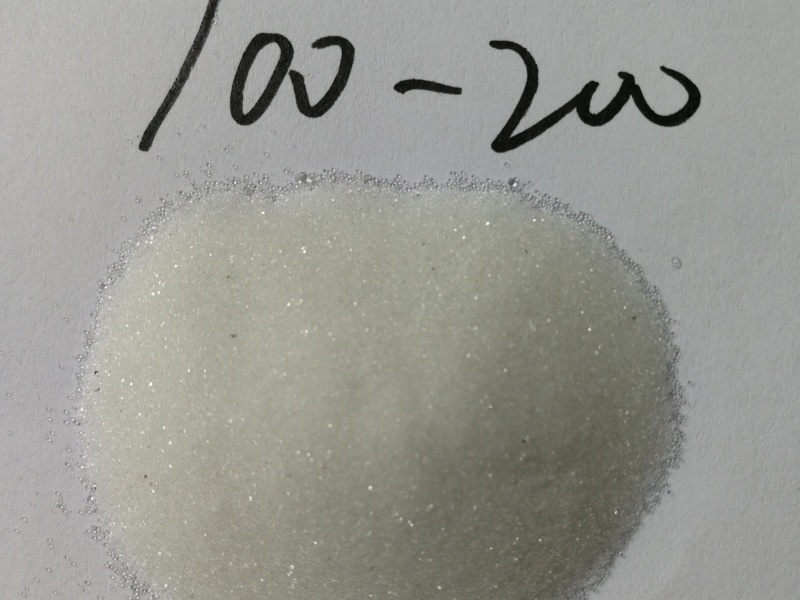

Customizable Finishes: By adjusting the size and pressure of the glass beads, different surface finishes can be achieved, allowing for customization based on specific requirements.

Minimal Dust Production: Glass beads produce minimal dust compared to other abrasive media, reducing the risk of respiratory issues and environmental contamination.

Reusability: High-quality glass beads can be reused multiple times, making them a cost-effective and environmentally friendly option for surface finishing.

Blasting glass beads is an effective and versatile method for enhancing surface finishing. Its ability to provide a uniform texture, gentle cleaning, improved adhesion, stress relief, and aesthetic enhancement makes it a preferred choice in many industries. Whether you are looking to prepare a surface for coating, improve its durability, or simply enhance its appearance, glass bead blasting offers a reliable and efficient solution.