Selecting the appropriate size of glass beads for your sand blasting project is crucial for achieving the desired surface finish and efficiency. Glass beads come in various sizes, each suited for different applications and materials. Here’s a comprehensive guide to help you choose the right size of glass beads for your sand blasting project.

Surface Material:

Metal: For metals like aluminum, stainless steel, and brass, finer glass beads (70-140 mesh) are often preferred for a smooth finish.

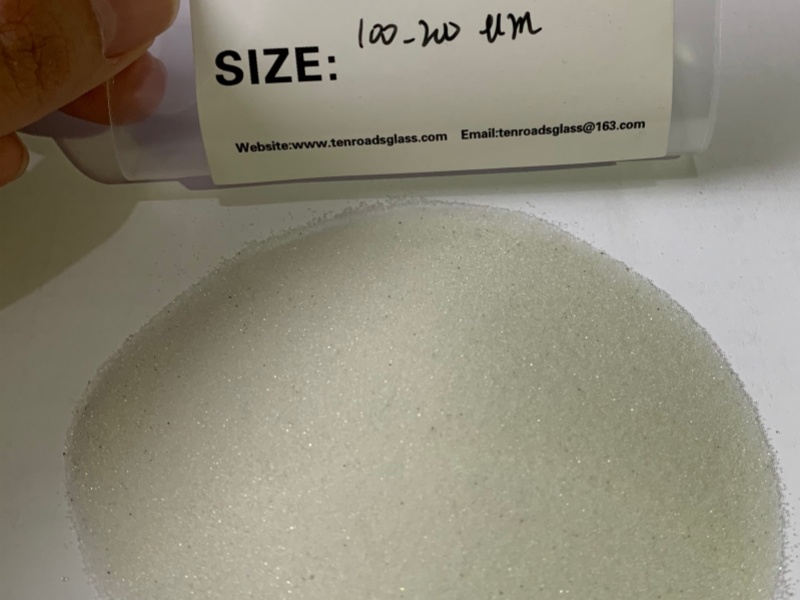

Plastic and Rubber: Use finer beads (100-200 mesh) to avoid damaging the surface.

Glass and Ceramics: Medium to fine beads (70-140 mesh) work well for cleaning and finishing without causing surface damage.

Desired Finish:

Smooth Finish: Finer beads (100-200 mesh) provide a smoother, more polished finish.

Matte Finish: Coarser beads (40-70 mesh) are better for achieving a matte or satin finish.

Textured Finish: Larger beads (20-40 mesh) can create a more textured surface.

Cleaning vs. Peening:

Cleaning: For removing rust, paint, and contaminants, medium-sized beads (60-100 mesh) are effective.

Peening: For surface strengthening and stress relief, finer beads (100-200 mesh) are typically used.

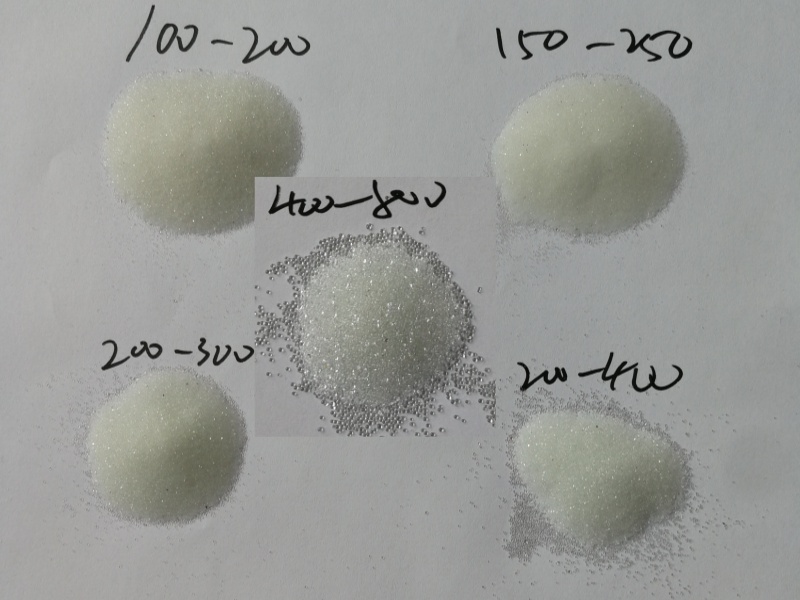

Mesh Size:

Mesh size refers to the number of openings per inch in a screen. A higher mesh number indicates finer beads.

Common mesh sizes for glass beads range from 20 to 200.

Grit Size:

Grit size is another way to measure bead size, often used interchangeably with mesh size.

Lower grit numbers indicate coarser beads, while higher numbers indicate finer beads.

Blasting Pressure:

Higher blasting pressures can handle coarser beads, while lower pressures are better suited for finer beads.

Ensure your equipment can accommodate the bead size you choose.

Nozzle Size:

The nozzle size of your blasting equipment should match the bead size. Larger nozzles can handle coarser beads, while smaller nozzles are better for finer beads.

Rust and Paint Removal:

Use medium-sized beads (60-100 mesh) for effective rust and paint removal without damaging the underlying material.

Surface Preparation for Coating:

For preparing surfaces for painting or coating, medium to fine beads (70-140 mesh) provide a clean, smooth surface.

Polishing and Finishing:

Finer beads (100-200 mesh) are ideal for polishing and finishing applications, providing a smooth, reflective surface.

Peening for Stress Relief:

Use finer beads (100-200 mesh) for peening applications to relieve surface stress and improve fatigue resistance.

Trial Runs:

Conduct trial runs with different bead sizes to determine the best fit for your specific project.

Evaluate the surface finish, cleaning efficiency, and overall effectiveness.

Adjust as Needed:

Based on the trial results, adjust the bead size, blasting pressure, and nozzle size to optimize performance.

Expert Advice:

Consult with your glass bead supplier for recommendations based on your specific application and equipment.

Suppliers can provide detailed information on bead size, material compatibility, and optimal usage.

Quality and Consistency:

Ensure you source high-quality glass beads with consistent sizing to achieve uniform results.

Choosing the right size of glass beads for your sand blasting project involves understanding your material, desired finish, and equipment capabilities. By considering these factors and conducting trial runs, you can select the optimal bead size to achieve the best results. Whether you’re removing rust, preparing surfaces for coating, or polishing materials, the right glass bead size will enhance the efficiency and quality of your sand blasting project.