TENROADS has recently sorted out the irreplaceable advantages of sandblasting shot glass beads in surface treatment, which can be used as a reference for customers in the surface treatment industry and help glass beads play a greater role in the use.

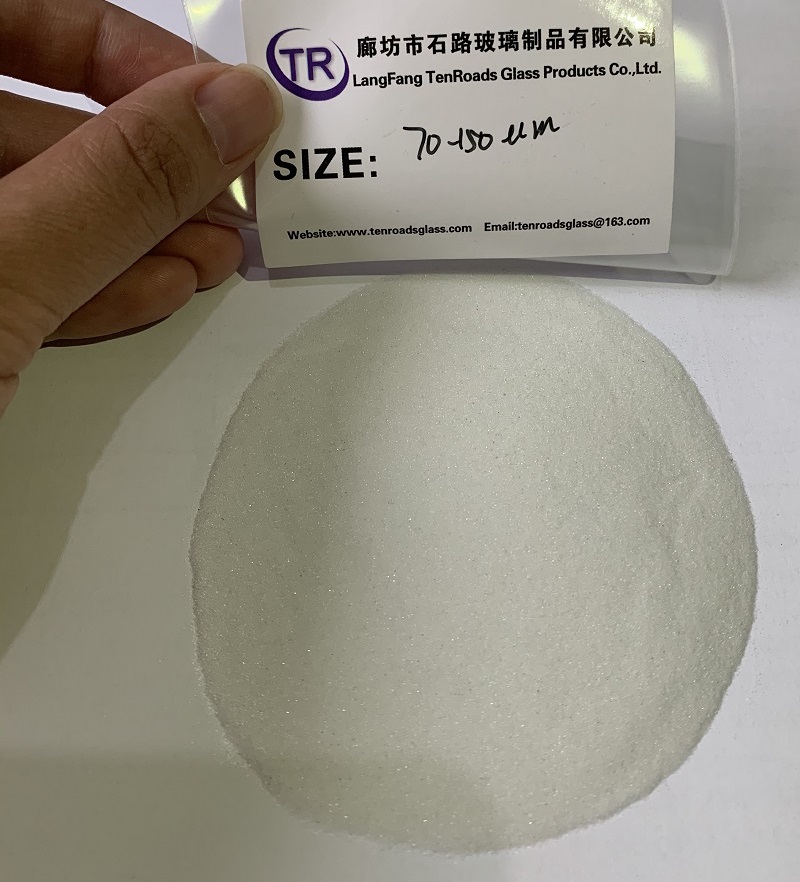

Glass beads, a kind of sandblasting consumables produced by the remanufacture of waste flat glass. At present, the market general standard for sandblasted glass beads has a maximum diameter of 850 μ m and a minimum diameter of 0 μ m. According to the commonly used specific interval granularity, it can be divided into 20, 30, 40, 60, 80, 100, 120, 150, 180, 220, 320, and can be graded according to different requirements.

In the process of sandblasting and shot peening for the surface treatment of different parts, in the selection of abrasives, glass beads are often used in the matte treatment of all kinds of stainless steel products, the cleaning of various moulds, the removal of tensile stress of all kinds of machine parts, the shot peening and polishing processing of all kinds of hardware products, the surface treatment of all kinds of non-ferrous metal pipes and precision castings, removal of burrs, removal of oxides, removal of rust inside and outside of all kinds of machines, polishing and roughing. Remove stress, surface treatment of all kinds of accessories and parts.

Among all kinds of sandblasting surface treatment consumables, compared with steel shot and stainless steel shot, the particle size of glass ball is smaller than 0.15mm. Steel shot and stainless steel shot are widely used in the surface treatment of metal shot blasting and some larger parts. Glass beads are more suitable for precision castings and non-ferrous metal devices. In precision castings and non-ferrous metal devices, steel shot will deform the parts and leave traces and eliminate excessive stress. Glass beads can be produced to less than 0.05mm, the appropriate size type and parts contact area is smaller, not easy to damage the surface of parts, stress relief is more uniform, matte treatment effect is better.

Compared with water chestnut glass sand, diamond sand, quartz sand and other consumables with water chestnut, sandblasting glass beads also have irreplaceable advantages. Because the water chestnut consumables are generally irregular or with edges and corners, no matter the particle size, they basically have some damage to the sprayed workpiece, which will show some traces under the microscope, which is easy to cause surface pollution and corrosion, and it is difficult to achieve long-term effect. After shot peening, glass beads rarely leave traces on the surface of industrial devices and have a long-term unchanged effect.

With regard to the use of glass beads that are not durable, sandblasted glass beads can be divided into natural gas glass beads and coking gas glass beads according to the production process. Coking gas glass beads can generally be recycled 1-2 times in use efficiency, while natural gas glass beads can be recycled 3-4 times according to practical application. In addition, the fan pressure and the ratio with other consumables also partially affect the durability.

The treatment effect of natural gas glass beads is also better than that of coking gas glass, which can be obviously compared in the actual use of customers. Therefore, the actual technical support for the use of glass beads becomes particularly important. With regard to the renewable advantages of glass beads, glass beads produced by remanufacturing waste flat glass also have long-term sustainable development advantages and cost advantages compared with other mineral consumables.

Please feel free to contact us if you need to buy them, we welcome your inquiries.