Industrial cleaning is a critical process in various sectors, including automotive, aerospace, construction, and marine industries. Effective cleaning ensures the longevity and performance of machinery, components, and structures. One of the most versatile and efficient methods for industrial cleaning is shot blasting with glass beads. This article delves into the advantages and applications of using glass beads in shot blasting, highlighting their role as a versatile solution for industrial cleaning.

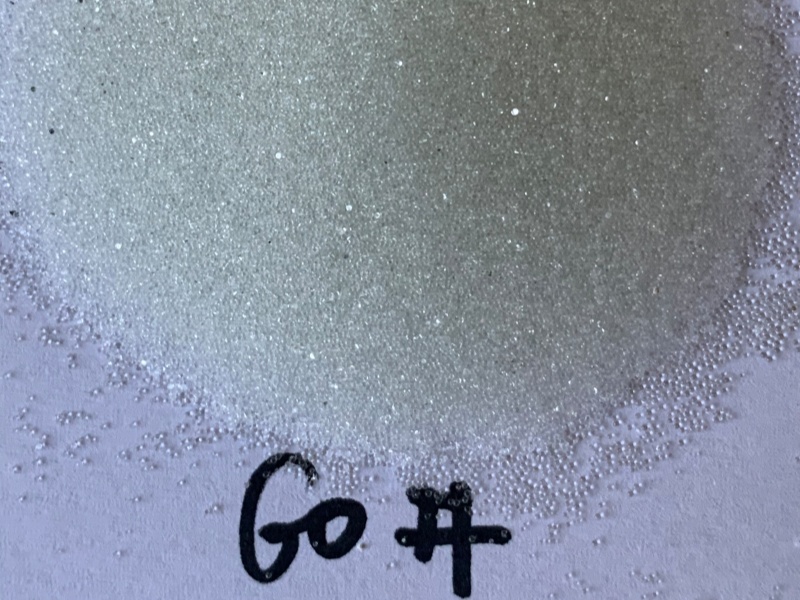

Shot blasting is a process that involves propelling abrasive materials at high speeds to clean, smooth, or prepare surfaces. The abrasive materials, known as “shots,” can vary in size, shape, and composition. Glass beads are a popular choice due to their unique properties and benefits.

Versatility: Glass beads are suitable for a wide range of materials, including metals, plastics, and composites. This versatility makes them ideal for various industrial applications.

Non-Abrasive Nature: Glass beads are less abrasive compared to other blasting media, such as steel shots or aluminum oxide. This makes them perfect for cleaning delicate surfaces without causing damage.

Consistent Finish: Glass beads provide a uniform and smooth finish, which is essential for applications requiring high precision. This consistency reduces the need for additional finishing steps, saving time and resources.

Reusability: Glass beads can be recycled multiple times without losing their effectiveness. This reusability makes them a cost-effective option in the long run.

Reduced Dust Generation: Unlike other abrasive materials, glass beads do not produce harmful dust particles. This improves air quality and reduces the need for extensive cleanup, enhancing operational efficiency.

Chemical Inertness: Glass beads are chemically inert and non-toxic, ensuring that they do not react with the surfaces being cleaned or contaminate the environment.

Automotive Industry: Glass beads are used for cleaning and preparing car parts, such as engine components, transmission parts, and body panels. Their non-abrasive nature ensures that delicate parts are not damaged during the cleaning process.

Aerospace Industry: In the aerospace sector, precision is paramount. Glass beads are used for cleaning and surface preparation of aircraft components, ensuring optimal performance and safety.

Construction Industry: Glass beads are employed to remove paint, rust, and other contaminants from building surfaces. They provide an efficient and eco-friendly solution for maintaining and refurbishing structures.

Marine Industry: Glass beads are used in the maintenance and refurbishment of ships and other marine structures. They effectively remove marine growth, rust, and old paint, providing a clean surface for new coatings.

To maximize the benefits of using glass beads in shot blasting, consider the following steps:

Assessment: Evaluate your current cleaning methods and identify areas where glass beads can be integrated.

Training: Educate your workforce on the proper handling and recycling of glass beads to maximize their lifespan and effectiveness.

Equipment Compatibility: Ensure that your shot blasting equipment is compatible with glass beads to achieve optimal performance.

Monitoring: Regularly monitor the effectiveness and environmental impact of using glass beads to make continuous improvements.

Shot blasting with glass beads offers a versatile and efficient solution for industrial cleaning. Their non-abrasive nature, consistent finish, reusability, and reduced dust generation make them an ideal choice for various applications. By adopting glass beads in shot blasting, industries can achieve higher quality results while also contributing to environmental sustainability. As the demand for eco-friendly and efficient cleaning solutions continues to grow, glass beads are poised to play a crucial role in the future of industrial cleaning.