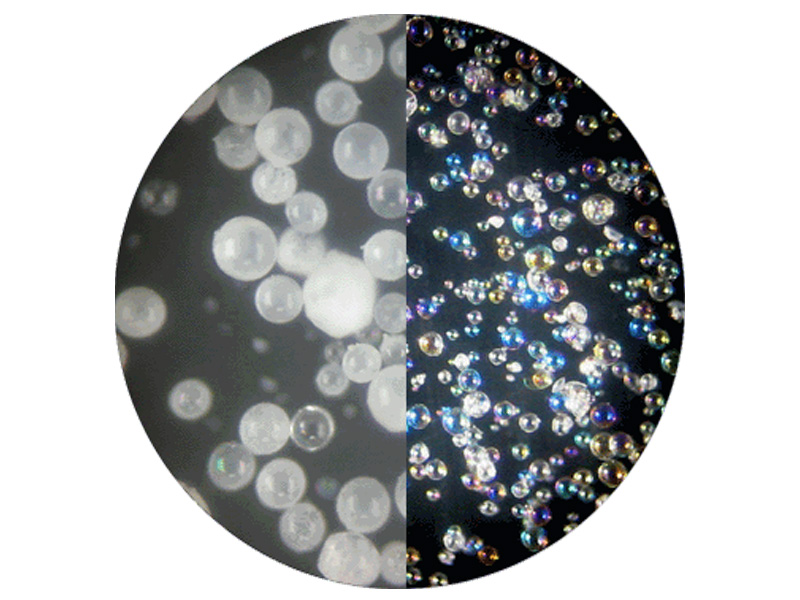

Glass microspheres, also known as hollow glass beads, have been in use for at least 100 years. Hollow glass microsphere technology was developed in the 1950s as a product of manufacturing solid glass beads. Since that time, many industries have come to rely on both solid and hollow glass microspheres as a major component of their products and processes.

Initially used primarily as a filler for plastics in the 1960s, it was used in many industries and thousands of applications, including aerospace and military materials, molded plastic parts, reflective highway signs, oil and gas, recreation, paints and coatings, transportation, construction, mining explosives, personal care, cosmetics and consumer products. In recent years, glass microspheres have experienced outstanding growth due to the emergence of new high-value, high-growth industries and the market for high-quality glass microspheres with perfect sphericity, tight tolerances and particle size distribution. These industries include biomedical, life sciences, microscopy, automotive, high-tech devices and specialty applications.

High strength, low density hollow glass microspheres can be used as lightweight additives in a variety of polymers and applications while maintaining or improving processability and material physical properties, including.

1) Polyolefins, nylon composites and other thermoplastics

2) Thermosets, liquids and pastes

3) Sheet molding and bulk molding composites

4) Elastomers

5) Alternative wood/polymer composites

Microspheres can withstand the processing conditions such as temperature and pressure of manufacturing processes such as blending, injection molding, and extrusion. Proper use can improve product quality by

Firstly, the density of glass microbeads is 0.4-0.75g/cm3, which reduces the density of composite materials and achieves weight reduction. Secondly, due to the characteristic of hollow, the use of resin is reduced while satisfying the performance; the development of aviation light weight.

Since the inside of glass beads is air, the dielectric constant of air is 1, which makes the overall dielectric constant of hollow glass beads very low, reducing the loss of high frequency signals, very suitable for 5G industry and self-driving cars...

Hollow glass microspheres are tiny spheres that act as miniature ball bearings in the resin, providing better flowability than flake, needle or irregularly shaped filler particles. The resulting microsphere effect reduces the viscosity of the mix, filling performance is naturally excellent, and good processing performance can improve productivity by 15% to 20%.

Since spherical objects are isotropic, filling microbeads can overcome the disadvantage of inconsistent shrinkage rate in different parts caused by orientation, ensure the dimensional stability of products, reduce warpage, and solve the problem that has always existed. Molding of shaped materials and large injection products. Deformation problem. In addition, hollow glass microspheres as fillers improve the processing speed of filled and modified materials and increase production efficiency.

The oil absorption rate of hollow glass microspheres is 0.20~0.60cc/g. Due to its spherical structure, the specific surface area per unit volume is low and the oil absorption value is low.

The density of high performance hollow glass microspheres is only 1/5~1/2 of the density of resin, and only a small amount of hollow glass microspheres is needed to replace other heavier powder materials in the same volume. When considering the cost per unit volume, the weight of the product can be reduced after filling, thus reducing the amount of resin and rubber, the main raw material, and lowering the cost of the product.

Hollow glass microspheres are rigid particles in themselves, and the addition of resin can improve the compressive strength and modulus of the material. At the same time, because the inside of glass beads is air, air has low thermal conductivity, and the porous material will absorb the vibration of sound waves, thus reducing the heat and hindering the propagation of sound waves.

TENROADS is a professional manufacturer of glass beads, our products include road marking glass beads, sandblasting glass beads, color reflective fire glass and other industrial glass beads. Please contct us if you need to know more.