Glass beads are a popular choice for sand blasting due to their unique properties and numerous benefits. Here are the top 5 reasons to choose glass beads for your sand blasting needs:

Consistent Texture: The spherical shape of glass beads ensures a uniform impact on the surface, resulting in a consistent and smooth texture. This is particularly important for applications requiring a high-quality finish.

Versatile Finishes: Glass beads can create a range of finishes from matte to satin, enhancing the visual appeal of the product.

Non-Abrasive Nature: Glass beads are less abrasive compared to other blasting media like aluminum oxide or silicon carbide. This makes them ideal for delicate surfaces that require cleaning or polishing without significant wear or damage.

Surface Preservation: The gentle action of glass beads helps preserve the integrity of the material, extending its lifespan and maintaining its structural properties.

Surface Preparation: Blasting with glass beads creates a slightly roughened surface, which improves the adhesion of coatings, paints, and other finishes. This ensures that the applied layers bond effectively and last longer.

Enhanced Coating Performance: Better adhesion leads to improved performance and durability of the coatings, reducing the need for frequent maintenance or reapplication.

Minimal Dust Production: Glass beads produce minimal dust compared to other abrasive media, reducing the risk of respiratory issues and environmental contamination.

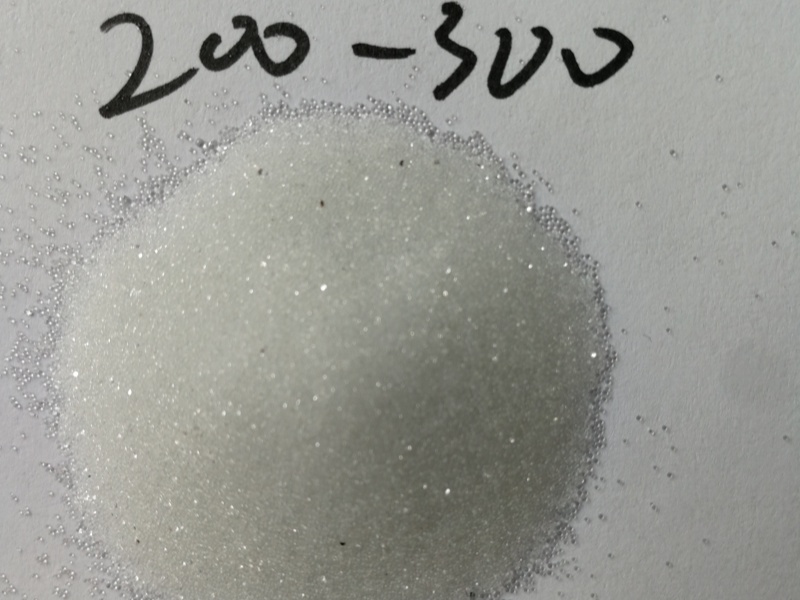

Reusability: High-quality glass beads can be reused multiple times, making them a cost-effective and environmentally friendly option for surface finishing.

Inducing Compressive Stress: Glass bead blasting can induce compressive stress on the surface of metal parts, a process known as peening. This helps to relieve tensile stress, which can lead to cracks and failures.

Increased Fatigue Resistance: By reducing tensile stress, glass bead peening enhances the fatigue resistance of the material, making it more durable and less prone to failure under cyclic loading.

Choosing glass beads for sand blasting offers numerous advantages, from achieving a uniform and high-quality surface finish to preserving the integrity of delicate materials. Their gentle, non-abrasive nature, combined with their ability to improve coating adhesion and provide stress relief, makes them an excellent choice for a wide range of applications. Additionally, their environmental benefits and reusability make them a cost-effective and sustainable option for surface finishing.